About The Henry Perkins Company

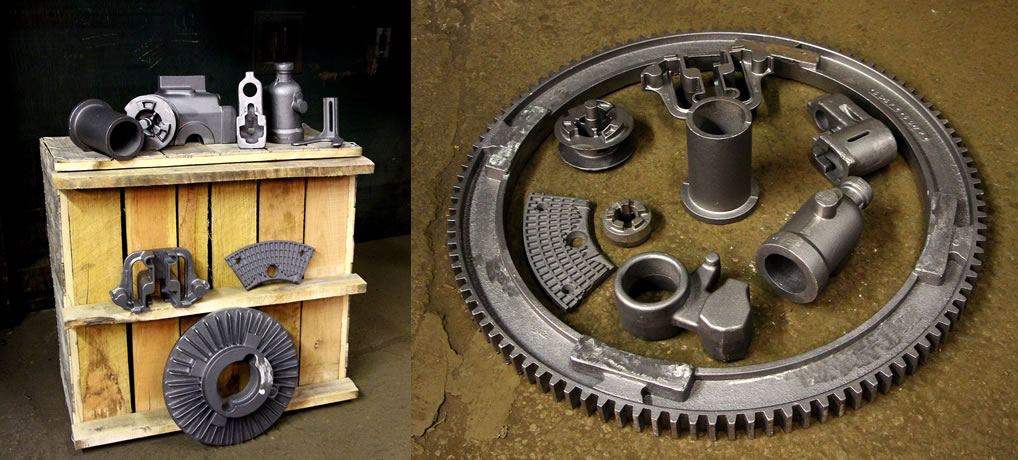

The Henry Perkins Company is one of the longest continually running foundries in the United States and it currently holds the distinctly as the only certified Meehanite® foundry in any of the east coast states. If you need Meehanite® parts and you are in or near the New England states, the Henry Perkins Company may be a good fit for your needs.

The company has a long history and has been in the same family for five generations, yet The Henry Perkins Company has invested in the future, with equipment and technologies ready to take on the 21st century.

Here are some highlights about The Henry Perkins Company:

- ISO 9001:2008 Certified

- Using 3D modeling

- Materials lab

- Sand lab

- Mold types: Green Sand and No Bake

- Ideal weights: a few ounces to 4,000 pounds

- Ideal manufacturing Volumes: small to medium volume parts

- Metals: Meehanite®, Gray Iron, Ductile Iron, Special Alloys (including Ni-Hard and Ni-Resist)

- Specifications: ASTM, ASM, SAE, AMS, and MIL

History of The Henry Perkins Company:

Founded in 1848, by Henry Perkins, The Henry Perkins Company started by casting cotton gin plate castings and piano plate castings out of grey iron. Leadership of the company has passed down through five generations with Tom, David, and Peter Perkins running the company today.

Does that mean The Henry Perkins Company is just another aging foundry? The Perkins family feels they have the right mix of history and forward momentum.

The foundry has the necessary experience providing the knowledge to consistently give you the highest quality. At the same time, the team works on keeping up with industry changes. Tom Perkins, the current president, even spent a few years working in German foundries before coming back and working at the family business, giving the company a broader experience than “just your average foundry.”

The Henry Perkins Company started casting Meehanite® parts beginning in 1939 as the foundry grew into casting parts with higher strengths, better wear resistance, and better overall uniform properties.

What Does the Henry Perkins Team like About Meehanite®?

Meehanite® offers The Henry Perkins Company customers with strong parts with excellent wear resistance, saving on the amount of material needed and extending the life of the components. The unique benefits of Meehanite® create an ideal solution for many customers who need the precision and quality needed in today’s world.

ISO 9001 Certified Foundry

The Henry Perkins Company has been using its ISO 9001:2008 certified Quality Management System for several years now, only improving on their long history of high quality production. You can view their current ISO certificate here.

True Quality at the “Core”

The Perkins Team believes quality is at the “core” of what they do. Quality goes deeper than pouring the right amount of metal into a mold. For The Henry Perkins Company, quality starts at the mold design stage, ensuring the part not only has the right shape, but also the flow into the mold and the cooling of the material is just right for the component to perform as it needs to in real life.

The Perkins team also knows how properly designed and assembled cores in the mold can make a huge difference. Tom Perkins shares, “We get a lot of customers from competitors because we know how to deal with complex designs that other companies struggle with.” That knowledge carries over to simple designs too where The Henry Perkins Company can make even simple cast parts better than some of their competitors.

Quality carries over to everything, from the proper cleaning of tools, molds, and equipment, to what happens in the quality assurance department. The Henry Perkins Company strives for excellence in quality, which has resulted in extremely low scrap rates for the industry and even carries over to high on-time delivery since there are so few surprises.

Where The Henry Perkins Company Really Shines

The team at Henry Perkins Company can show their exceptional talent when working with complicated molds, especially molds with multiple cores. Getting these complicated parts cast with consistently high quality and avoiding scrap has long been a specialty at this foundry. Does that mean they don’t do “simple parts?” Tom Perkins shared they love doing simple parts as much as they love casting complicated parts. Yet even then, the trained eyes of the experienced Henry Perkins team can find opportunities even with some “simple” parts that other foundries may miss. That is the difference you get when you have a well-trained team with the right knowledge base.

Other Advantages to Working with The Henry Perkins Company

The Henry Perkins Company foundry is debt free and sees a bright future before it. That makes a real difference in an industry where dozens of companies close their doors for good every year because of bankruptcy, acquisition, or the ownership just no longer has interest in the foundry industry. Many castings buyers have been surprised when their tools have been locked behind the doors of a company that folded, which is not a risk with the Perkins family.

The Henry Perkins Company also has a large degree of flexibility in metals they can cast as well as the size and volume you can cast. Life is a lot easier when you can go to one source to cast 1,000 pieces of a half-pound casting and still order a single casting weighing a ton or more. The company has the ability to handle low and mid-range volume production. The team can also pour up to 4,000 pounds of metal as a single casting.

Interested in Learning More About The Henry Perkins Company?

You can learn more about The Henry Perkins Company at their website. You can also give them a call to see how they can add value to your own company. Be sure to ask the Perkins family specifically how Meehanite® castings can improve your quality at a favorable cost to bring more to your bottom line.